Anti -static floor

Classification:

Application Scenario

Key words:

Application Scenario

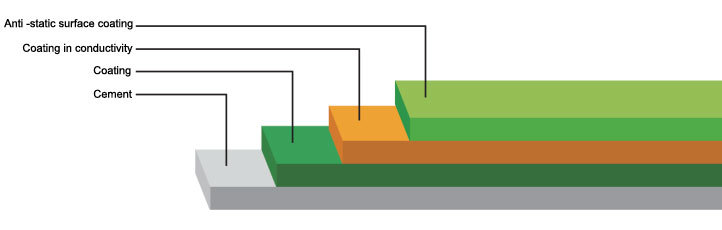

Anti -static floor is a specially designed floor material that can effectively prevent static accumulation and suitable for places that need to prevent static sparks.

Scope

For electronics, computers, communications, precision machinery, chemistry, military workers, aerospace and other manufacturing workshops, the floor of the manufacturing workshop requires antistatic places.

Performance characteristics:

1. The anti -static performance is good, which can effectively reduce the accumulation of static electricity and prevent static sparks.

2. wear resistance, corrosion resistance, impact resistance, long service life.

3. Simple construction and convenient maintenance.

4. Various colors can meet the beauty needs of different occasions.

5. Environmental protection, no pollution.

Construction method:

On the surface of the floor of the Tehli epoxy primer, the following method is used to paint

1. Prime painting: Stir the component A evenly, and prepare according to the proportion of composition A and B; stir well and construct it with a scraper or a drum.

2. Laying ground copper wire and conductive system network in order to release static electricity.

3. Apply scraping anti -static electricity: After the copper and copper foil is laid, apply the anti -static batch with a scraper to cover the copper foil.

4. After coating is completely dry, polish it with a polished machine and sandpaper to grind the generated knife marks and particles, and clean it with a vacuum cleaner.

5. Rolling top paint: After the surface paint is adjusted properly, the floor is evenly applied with the performance method (you can also apply it with spraying). If you need it, you can roll the paint for the second time. The method is the same.

PRODUCTION BASE

The company is committed to product technological innovation and building new platforms to improve its capabilities. In order to continuously improve its core competitiveness in the market and meet new market demands, Des-Lead has established a research and development center. The company has more than 10 professional R&D teams in the fields of flooring, sports, waterproofing and anti-corrosion, and polyurea. It continues to research products that better meet market needs, pays attention to ecological construction, and actively tries environmental protection technology. It has maintained vigorous vitality and abundant market vitality in the fierce market changes and market competition.

PRODUCTION LINE

Des-Lead has its own independent production base and has established a world-leading fully automatic assembly line with a comprehensive daily output of 100 tons and an annual service site area of more than 10 million square meters. The strict quality management system ensures the quality and efficiency of Des-Lead products.

RELATED PRODUCTS

ONLINE MESSAGE