Desili polyurea sports stand construction secret, fast code live!

Release time:

2024-11-30

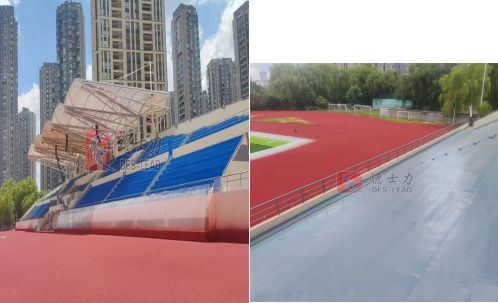

In the construction process of stadiums, the sports stands painted with Texili polyurea material are widely popular because of their many advantages.

Texili polyurea sports stands

In the construction process of stadiums, the sports stands painted with Texili polyurea material are widely popular because of their many advantages.

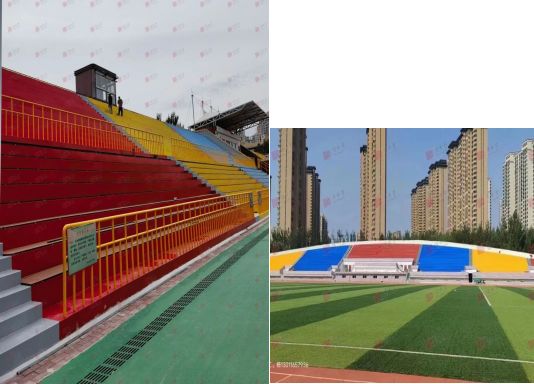

The Texili polyurea material exhibits excellent wear resistance and can withstand the friction generated by the frequent movement and sports activities of many spectators, thereby maintaining the smooth and beautiful surface of the stand for a long time.

Its excellent weather resistance means that whether it is in the sun, wind and rain erosion or extreme temperature changes, the grandstand will not easily age, fade or crack problems, significantly extending the service life of the grandstand.

In addition, Texli polyurea also has good water resistance and corrosion resistance, effectively preventing the damage caused by rain infiltration on the structure of the stand, even in high humidity or chemical pollution environment can remain stable.

However, to build a high-quality polyurea sports stand, the construction process is more complicated than it appears. This article will explain in detail the matters that need attention during the construction of polyurea sports stands.

Desili polyurea sports stand construction technology

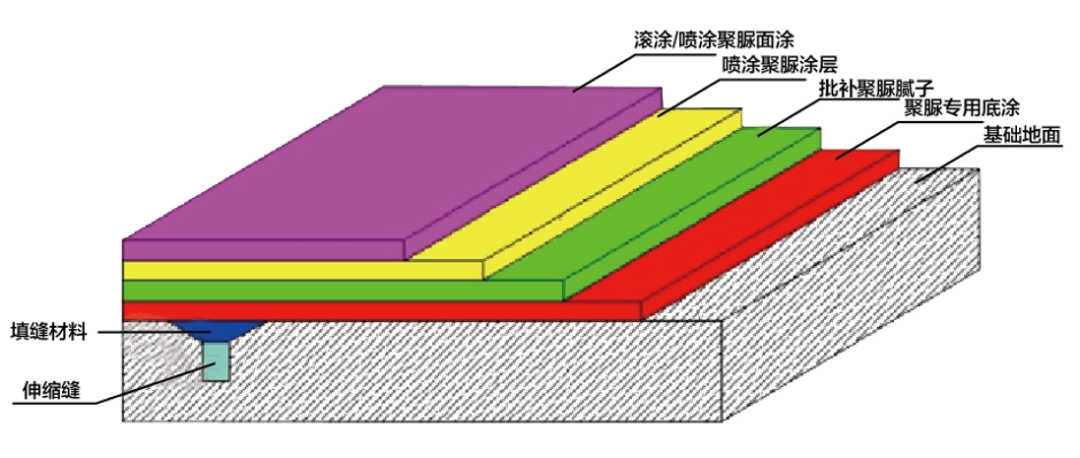

01 Basic Ground processing

Carry out thorough polishing treatment to make the surface of the sports stand solid and smooth. If there are defects such as honeycomb, pockmarked surface and cracking, repair materials should be used to repair and smooth; Residues such as oil, salt, and solvents need to be removed to ensure durability. For the old concrete foundation stands, the plastering mortar can be mixed with 108 glue, and the whole spread and scrape 1-2 times until the foundation meets the construction requirements.

02 Apply polyurea primer

Rolling coating or spraying on the base floor can close the surface pores, reduce the coating defects after spraying, and increase the bonding force between the polyurea coating and the cement and concrete floor, until it is completely cured, the next step can be carried out. Large areas of exposure should be repainted to the ground dark brown.

03 batch polyurea filler

A polyurea putty is applied with a scraper, the ground is levelled and the overall thickness is increased. After it is completely cured, the overall grinding is carried out with a sander, and the holes, honeycomb structure and defect holes are repaired twice. After dust removal, the next step of construction is carried out.

04 Apply polyurea primer

A small amount of roll coating or spray polyurea coating, it is recommended to spray to form a spot-like non-film distribution. Primer curing standard: polyurea spraying can be carried out without material and obvious liquid.

05 Stress point reinforcement

The position of the Yin Angle, the Yang Angle, the groove and the metal embedded parts are pre-strengthened, and a polyurea elastomer is sprayed as the strengthening layer, the general thickness is 0.5mm and the width is 300mm, depending on the actual situation on the site.

06 Spray polyurea

Adopt the order of first up and then down and then bottom, the method of small area cross-cross movement, the moving speed according to the thickness of each layer 0.35 ~ 0.50mm, each spray width should be less than 1200mm, the overlap width between adjacent spray layers should be greater than 120mm. At the same time, it is necessary to clean up the pollutants under the feet and brought into the pipeline at any time to avoid the quality of the garbage.

For places where anti-slip requirements are high, artificial granulation can be performed on the wet coating.

During the spraying process, the thickness of the coating should also be tested at any time, and the parameters such as pressure and temperature should be observed at any time, and on-site records should be made.

07 Apply polyurea top paint

Polyurea surface coating material is used to improve the polyurea coating surface anti-ultraviolet radiation, prevent aging, discoloration, improve the wear resistance of polyurea coating, protect the polyurea coating coating.

The use of special roller tools, the polyurea surface coating material evenly rolled over, as far as possible to reduce the construction joint, should be coated within the specified time, and pay attention to the connection of the front and back group of materials, impurities found in the construction should be removed immediately. During the construction and maintenance time, control personnel in and out, such as when the construction temperature is 10-15 degrees, the maintenance time is 24 hours to 48 hours. The adhesion test of polyurea coating can be carried out 7 days after completion of construction.

Desili polyurea sports stand construction precautions

1. Before construction, the substrate must be strictly inspected to ensure that it meets the construction standards. If cracks, hollows or other defects are found in the substrate, they must be repaired or replaced to ensure the integrity and durability of the final coating.

2. In the construction process of polyurea materials, it is necessary to ensure the normal operation of the spraying equipment. Any equipment failure can result in uneven coating and affect the overall performance of the coating. Therefore, the equipment status should be checked before construction, and regular maintenance and inspection should be carried out during the construction process.

3. The construction environment has an important impact on the curing process of polyurea materials. Construction should be avoided in rainy days or environments with high humidity, because moisture will interfere with the curing reaction of the material, resulting in decreased coating performance. Choosing dry and well-ventilated weather for construction is the best choice.

4. Construction personnel must wear appropriate protective equipment during operation, such as protective clothing, gloves, goggles, etc., to prevent polyurea materials from coming into contact with the skin or eyes, causing unnecessary injury. At the same time, construction personnel should receive professional safety training to understand the characteristics of materials and emergency treatment measures.

5. After the completion of construction, the spraying equipment and tools should be cleaned in time to prevent the polyurea material from curing inside the equipment, resulting in damage to the equipment or inconvenience during next use. Cleaning should be performed using appropriate solvents and in accordance with the equipment manufacturer's instructions.

Related News

[Policy dividend + Technology break] Old change floor upgrade, Des-Lead polyurea how to help you worry and save money?

2025-03-22

Stand renovation revolution Why polyurea materials become the new favorite?

In recent years, with the continuous upgrading of stadiums and large event venues, the renovation of stands has become a hot topic. Among the many refurbished materials, polyurea materials stand out and become the first choice for more and more projects. So, what is the charm of polyurea that can set off a revolution in the field of grandstand renovation?

2025-03-22

Texili polyurea flooring: A new trend for quality garage flooring

With the acceleration of urbanization, the design and construction of underground garages, as an important part of modern architecture, are paid more and more attention. Garage floor as a bridge connecting vehicles and buildings, its performance and quality are directly related to the overall performance of the garage. Although the traditional concrete floor is cheap, it is easy to wear and dust, and it is difficult to meet the needs of modern garages. Therefore, floor materials with stronger wear resistance and lower maintenance costs have gradually become the mainstream choice.

2024-11-23

Desili polyurea sports stand construction secret, fast code live!

In the construction process of stadiums, the sports stands painted with Texili polyurea material are widely popular because of their many advantages.

2024-11-30