Handmade Polyurea

Tension strength, MPa:≥10

Elongation of break, %:≥300

Tear strength, KN/m:≥40

Water absorption rate, %:≤5.0

Classification:

Polyurea

Key words:

Polyurea

Performance metrics

| No | Test Items | Test Standards | Requirement | Test Results | Conclusion | Remarks | |||

| 1 | Coated Appearance | GB/T 22374-2018 6.3.4 | Surface flat, no visible shrinkage holes, floating color, flowering, wrinkle, pinholes, cracking and other phenomena | Compare | Qualified | ||||

| 2 | Water resistance (168h) | GB/T 9274-1988 C method | No bubbles, no peeling, allow slight discoloration, and recover after 2 hours | Compare | Qualified | ||||

| 3 | Alkaline resistance (20%NaOH),72h | GB/T 9274-1988 C method | No bubbles, no peeling, allow slight color change | Compare | Qualified | ||||

| 4 | Acid resistance (10%H,S0,),48h | GB/T 9274-1988 C method | No bubbles, no peeling, allow slight color change | Compare | Qualified | ||||

| 5 | Oil resistance (120# solvent oil), 72h | GB/T 9274-1988 C method | No bubbles, no peeling, allow slight color change | Compare | Qualified | ||||

| 6 | Low temperature bending, ℃ | GB/T 16777-2008 14.2.1 | ≤-35 | -35℃ pass | Qualified | ||||

| 7 | Impermeable | GB/T 16777-2008 15 | 0.4MPa, 2h impermeable water | 0.4MPa,2h impermeable water | Qualified | ||||

| 8 | Heating expansion rate, % | GB/T 16777-2008 12 | Elongation or contraction≤1. | Elongation 0.8 | Qualified | ||||

| 9 | Binding strength, MPa | GB/T 16777-2008 Chapter 7 Law A | ≥2.0 | 3.05 | Qualified | ||||

| 10 | Hardness (Shao A) | GB/T 531.1-2008 | ≥70 | 81 | Qualified | ||||

| 11 | Nonvolatile content, % | GB/T 1725-2007 | ≥96 | 98.2 | Qualified | ||||

| 12 | Drying Time | Table drying time, h | GB/T 1728-2020 | ≤4 | 4h pass | Qualified | |||

| Term time, h | GB/T 1728-2020 | ≤24 | 24h pass | Qualification | |||||

| 13 | Tension strength, MPa | GB/T 528-2009 15.2.2 | ≥10 | 10.83 | Qualification | ||||

| 14 | Elongation of break, % | GB/T 528-2009 15.1.2 | ≥300 | 415 | Qualification | ||||

| 15 | Tear strength, KN/m | GB/T 529-2008 | ≥40 | 40.6 | Qualification | ||||

| 16 | Water absorption rate, % | HG/T 3344-2012 | ≤5.0 | 3.5 | Qualification | ||||

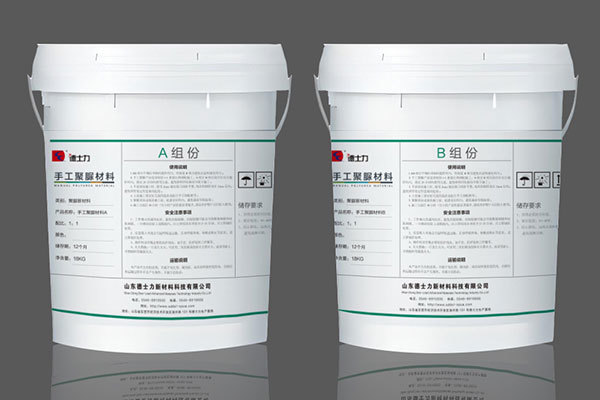

Product Overview

Handmade polyurea elastomer is a solvent-free, two-component, hand-brushed polyurea elastomer material. The material is cured on site from semi-prepolymers, end amino polyethers, delayed diamine chain extenders and other raw materials to form elastic polyurea floor materials. The ratio of component A to component B is 1:1, where component A weighs 18kg and component B weighs 18kg.

Application scenarios

Widely used in industry, commerce, public facilities, sports venues and other fields. Its characteristics include wear resistance, pressure resistance, impact resistance, and chemical corrosion resistance, and is suitable for production environments, commercial places, parking lots, airports, stations, sports venues, etc. Polyurea flooring is also used for waterproof and wear-resistant projects on roofs, bridge decks, platforms, platforms, parking garages, as well as waterproof and wear-resistant projects on balcony surfaces.

PRODUCTION BASE

The company is committed to product technological innovation and building new platforms to improve its capabilities. In order to continuously improve its core competitiveness in the market and meet new market demands, Des-Lead has established a research and development center. The company has more than 10 professional R&D teams in the fields of flooring, sports, waterproofing and anti-corrosion, and polyurea. It continues to research products that better meet market needs, pays attention to ecological construction, and actively tries environmental protection technology. It has maintained vigorous vitality and abundant market vitality in the fierce market changes and market competition.

PRODUCTION LINE

Des-Lead has its own independent production base and has established a world-leading fully automatic assembly line with a comprehensive daily output of 100 tons and an annual service site area of more than 10 million square meters. The strict quality management system ensures the quality and efficiency of Des-Lead products.

RELATED PRODUCTS

ONLINE MESSAGE