Outdoor polyurethane floor

Classification:

Application Scenario

Key words:

Application Scenario

Product introduction:

Double -group modifiers with polyurethane coatings have good wear resistance, strong adhesion, low temperature resistance, impact resistance, and also have the characteristics of pollution -free, non -toxic, non -combustible, environmental protection and safety. Anti -corrosion flooring and a variety of functional floors such as conductive, non -slip type, flame retardant type, etc., get attention and application in more and more areas

Scope of application:

It is suitable for hotels, food factories, pharmaceutical factories, hospitals, schools, shopping malls, conference rooms, outdoor parking lots, sports stations, playgrounds, sidewalks, underground garages, instrument rooms, computer rooms and other places.

Performance characteristics:

1. Excellent weather resistance, abrasion resistance, and hardness;

2. Environmental protection, dustproof, and mildew;

3. Semethy, easy to clean, and good decorative effect;

4. General chemical corrosion such as water resistance, oil -resistant, acid and alkali resistance;

5. The effect of temperature and humidity is small, and has a good bonding strength on the wet surface.

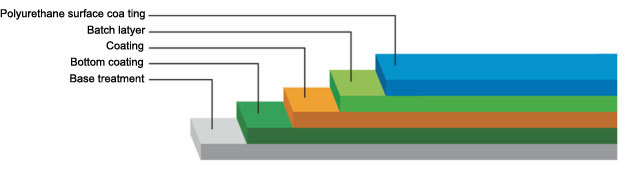

Construction process:

1. Grassroots treatment: thoroughly clean up the dust, oil and other impurities on the surface, and then use a vacuum cleaner to clean up to clean up the dust on the surface of the base material.

2. Bottom coating: After mixing the polyurethane bottom coating material, mixes and mix well in proportion. After the drum is evenly coated, there must be no leakage and leakage.

3. Mid-coating mortar layer: Use polyurethane material to mix in proportion, add an appropriate amount of quartz sand and stir well; scrape it with a batch knife for 1-2 times, the thickness is even, no obvious batch marks. No obvious cracks, concave pit and other phenomena are made on the surface of the floor. After it is solidified, polish the defects such as the batch knife batch marks, and it must be used to suck it with a vacuum cleaner until the granular is not available before the lane process operation can be performed.

4. Putty layer: After medium coating, use sandpaper to polish the floor, and use the putty of putty in water in the water -like coating with quartz powder according to the actual needs.

5. Noodle coating: Mix the components of polyurethane surface A and B as a proportion, stir well, and apply the water-based polyurethane surface with a tube to coat 1-2 times. Phenomenon. The mixing materials should be painted within the specified time. After completion, the overall ground is required to be soft, clean, and uniform in color, no empty drum;

6. Maintenance: The duration of the surface of the surface requires 24 hours. During this period, it should be closed to avoid affecting the clean and smooth effect of the surface. After 3 days, the person can be officially put into use after 7 days of completion and maintenance (based on 25 ° C, the opening time needs to be extended moderately at low temperature).

Technical indicator:

| Experimental project | indicator | |

| coating film appearance | The appearance of the coating film is normal | |

| dry time | Dry (h) | ≤4 |

| Standard (h) | ≤24 | |

| pencil hardness | ≥h | |

| wear resistance (750g/500R) | ≤0.04g | |

| adhesion, level | ≤1 | |

| pressure resistance, MPA | ≥80 | |

| water resistance | No foaming, not falling off, allowing slight discoloration | |

| impact resistance | 500g steel ball, 100cm high, no cracks in coating film, no & nbsp; peeling | |

| oil resistance | No foaming, not falling off, allowing slight color change | |

| temperature -resistant water | No foaming, not falling off, allowing slight color change |

Note:

1. Avoid the construction of the ambient temperature below 5 ° C, and the air humidity greater than 85%;

2. Construction site to prevent bright fires, strengthen ventilation, and ensure that the floor is completely dry before they can walk to the people;

3. During construction, it is strictly forbidden to bring impurities such as water, oil pollution into the construction work surface;

4. Polyurethane floor construction should avoid severe weather such as heavy fog, rain and snow, and high temperature.

PRODUCTION BASE

The company is committed to product technological innovation and building new platforms to improve its capabilities. In order to continuously improve its core competitiveness in the market and meet new market demands, Des-Lead has established a research and development center. The company has more than 10 professional R&D teams in the fields of flooring, sports, waterproofing and anti-corrosion, and polyurea. It continues to research products that better meet market needs, pays attention to ecological construction, and actively tries environmental protection technology. It has maintained vigorous vitality and abundant market vitality in the fierce market changes and market competition.

PRODUCTION LINE

Des-Lead has its own independent production base and has established a world-leading fully automatic assembly line with a comprehensive daily output of 100 tons and an annual service site area of more than 10 million square meters. The strict quality management system ensures the quality and efficiency of Des-Lead products.

RELATED PRODUCTS

ONLINE MESSAGE