Polycrostic anticorrosive elastic body

Classification:

Application Scenario

Key words:

Application Scenario

The field of anticorrosion is an earlier field of agglomeration technology and large engineering applications. Applications in its fields include the anti -corrosion of steel structures such as pipelines, tanks, docks, steel piles, and chemical storage tanks. The material coating is dense, seamless, strong anti -penetration and corrosion performance, can withstand the erosion of most chemical media, can be used in strong corrosive outdoor environments such as swamps, ponds, salt oil, and stone squares for a long time. , Crackless, not falling off, good weather resistance.

Scope of application:

01/Pipeline anticorrosion

Dushi Julin material can effectively prevent the corrosion of oil, natural gas, chemical industry and other industries. After the spray coating, a protective layer will form a protective layer on the surface of the pipeline to resist internal medium erosion, while improving wear resistance and impact resistance, reducing maintenance and replacement costs.

02/storage tank anti -corrosion

Dushi Gathering Materials provides anti -corrosion protection for industries such as chemicals, oil, food, etc., and form a solid anticorrosive layer by spraying or painting to prevent medium erosion. In addition, the coating of polychen coating enhances the sealing and temperature resistance of the tank, reducing leakage and volatilization.

03/floor anti -corrosion

Facilities such as chemical industry, food processing, and sewage treatment need to have strong anticorrosiveness. Delica Julin material is widely used because of its anti -chemical corrosion characteristics, which can resist the erosion of a variety of chemical substances, prolong ground life, and reduce maintenance costs. The Juli floor is also good waterproof to prevent liquid from penetrating and keep the environment dry and clean.

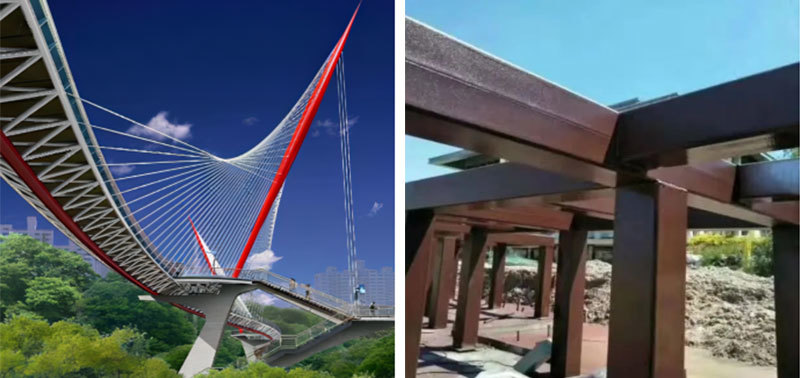

04/steel structure anticorrosion

The steel structure is widely used in many industries such as construction, bridge, and mechanical manufacturing, but it is easy to corrode. The Dushi Gathering Materials can effectively anticherably. By spraying or painting, a hard wear -resistant protective layer is formed to prevent rust and corrosion. At the same time, it will improve the weather resistance and beauty, and extend the service life.

05/Ocean Engineering Antibrium

Dushi Gathering Materials can effectively prevent corrosion in the marine environment, and is suitable for marine engineering facilities such as platforms, ships and pipelines. After spraying or brushing the coating, the surface of the facility forms corrosion -resistant and wear -resistant protective layers to resist seawater and salt mist erosion. At the same time, it enhances anti -impact and anti -fatigue performance, and extends the service life.

Performance advantages:

Dushili polychen is a high -performance elastic material, which is generated by the reaction of the isocyanate component with the amino compound component. It has many unique properties, such as high strength, high elasticity, wear resistance, corrosion resistance, aging resistance, etc. The polycase anticorrosive project can adjust its system structure according to different application needs to meet various complex anti -corrosion requirements.

1. Excellent corrosion resistance: Dushi Juli materials have a high degree of chemical stability, which can resist the erosion of a variety of chemical substances. It is suitable for chemical industry, petroleum, ocean and other industries, as well as infrastructure such as sewage treatment, bridges, tunnels and other infrastructure to provide effective effectiveness Anticorrosive protection.

2. Excellent wear resistance: In some occasions with severe wear, such as mines, ports, mechanical manufacturing and other industries, the abrasion resistance of Dushi Gathering Materials is particularly important. It can effectively resist friction and impact, reduce the wear and damage of the equipment, and extend its service life.

3. Fast solidification and convenient construction: The Dushi Gathering Materials quickly solidified to form anticorrosive coating, the construction is rapid, the construction period is shortened, and the impact is reduced. It is suitable for the protection objects of various construction methods and various shapes and sizes.

4. Good adhesion and flexibility: The Dushi Gathering Materials can firmly combine a variety of substrates to form continuous and dense anticorrosive coating, and have good flexibility, adapt to deformation vibration, and avoid cracking and falling off.

Technical parameter

| Summary of the test results | |||||||

| serial number | detection items | unit | Test results | indicator ① | detection conclusion | detection method | Remarks |

| 1 | Solid content | % | 99.6 | ≥98 | match | GB/T23446-2009 | 120 ℃, 3H |

| 2 | Gel time | s | 10 | ≤45 | match | GB/T23446-2009 | - |

| 3 | Table time | s | 12 | ≤120 | match | GB/T23446-2009 | Method: refers to the touch method |

| 4 | stretch strength | MPA | 17.2 | ≥16.0 | match | GB/T23446-2009 | No processing |

| 5 | Fracture and elongation | % | 578 | ≥450 | match | GB/T23446-2009 | |

| 6 | tear strength | n/mm | 56 | ≥50 | match | GB/T23446-2009 | - |

| 7 | Low -temperature bending | - | -40 ℃, no crack | ≤ -40 ℃ | match | GB/T23446-2009 | - |

| 8 | impermented | - | 0.4MPa, 2h, impermeable water | 0.4MPa, 2h, impermeable water | match | GB/T23446-2009 | - |

| 9 | Heating and retractable rate | - | elongated 0.3% | elongation ≤ 1.0% | match | GB/T23446-2009 | - |

| 10 | water absorption rate | % | 2.9 | ≤5.0 | match | GB/T23446-2009 | Soak in water for 7 days in water |

| 11 | Dingtian time aging | - | crackless and deformation | crackless and deformation | match | GB/T23446-2009 | Heating aging (80 ° C, 168h) |

| - | crackless and deformation | crackless and deformation | match | GB/T23446-2009 | Avalent climate (cycle A, irradiation strength 0.51W/m2, blackboard temperature 63 ° C, 38 ° C in the box, 250h) | ||

| 12 | thermal treatment (80 ° C, 168h) | ||||||

| Stretch strength maintenance rate | % | 94 | 80-150 | match | GB/T23446-2009 | - | |

| Fracture and elongation | % | 619 | ≥400 | match | GB/T23446-2009 | - | |

| Low -temperature bending | - | -35 ℃, no crack | ≤ -35 ℃ | match | GB/T23446-2009 | - | |

| 13 | Alkali treatment (0.1%NaOH+saturated CA (OH) 2, 168H) | ||||||

| Stretch strength maintenance rate | % | 81 | 80-150 | match | GB/T23446-2009 | - | |

| Fracture and elongation | % | 593 | ≥400 | match | GB/T23446-2009 | - | |

| Low -temperature bending | - | -35 ℃, no crack | ≤ -35 ℃ | match | GB/T23446-2009 | - | |

| 14 | acid treatment (2%H2SO4, 168H) | ||||||

| Stretch strength maintenance rate | % | 81 | 80-150 | match | GB/T23446-2009 | - | |

| Fracture and elongation | % | 629 | ≥400 | match | GB/T23446-2009 | - | |

| Low -temperature bending | - | -35 ℃, no crack | ≤ -35 ℃ | match | GB/T23446-2009 | - |

Construction process

1. Grassroots treatment: thoroughly clean and polish the construction surface to ensure that there is no dust, no oil, water -free and other pollutants on the surface. For the grassroots with cracks or unevenness, it is necessary to repair and find flat to ensure the adhesion and overall effect of the coating. If the foundation is made of metal, the metal sandblasting is needed to the SA2.5 level, and the sandblasting treatment is within 6 hours for the construction of polyclavia.

2. Apply -brushing primer: evenly apply the primer on the processing grass level. The primer can enhance the adhesion of the coating and the grassroots level, and provide a good attachment foundation for the subsequent polyclast main paint.

3. Spray the corruption coating: After the test spray is qualified, first spray the connection into the pores, and then the inner surface of the pipeline. The straight tube or elbow part is sprayed on the factory and sprayed on the joint site. Take up first, then down, and then the bottom, the small area of the cross -crossing movement is sprayed, the thickness of the coating is 1.5 to 2.0mm, and the spray is completed at one time. The paint of the main paint needs to be uniform and continuous, avoid leakage or uneven thickness, and ensure the integrity and anticorrosive effect of the coating.

4. Roll coating, spray polycramine surface coating: mix the main agent and curing agent by proportional, and use a dedicated drum to evenly roll or spray the coating coating on the surface of the fully solid. , Prevent aging and discoloration.

PRODUCTION BASE

The company is committed to product technological innovation and building new platforms to improve its capabilities. In order to continuously improve its core competitiveness in the market and meet new market demands, Des-Lead has established a research and development center. The company has more than 10 professional R&D teams in the fields of flooring, sports, waterproofing and anti-corrosion, and polyurea. It continues to research products that better meet market needs, pays attention to ecological construction, and actively tries environmental protection technology. It has maintained vigorous vitality and abundant market vitality in the fierce market changes and market competition.

PRODUCTION LINE

Des-Lead has its own independent production base and has established a world-leading fully automatic assembly line with a comprehensive daily output of 100 tons and an annual service site area of more than 10 million square meters. The strict quality management system ensures the quality and efficiency of Des-Lead products.

RELATED PRODUCTS

ONLINE MESSAGE