Polytewater waterproof elastic body

Classification:

Application Scenario

Key words:

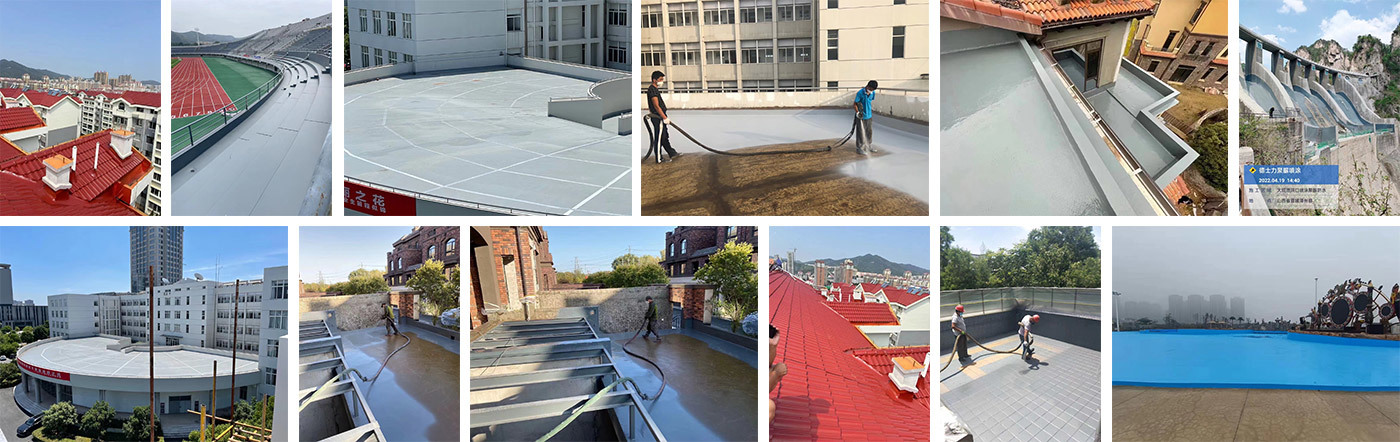

Application Scenario

Juliku materials, as a new star in the field of waterproof materials, have significantly surpassed traditional waterproof materials in many ways with their outstanding performance. The innovation of this material is that it can flexibly adapt to various waterproof needs. No matter what kind of environment or occasion, it can show its excellent waterproof effect. Therefore, pool materials have become an ideal choice in the field of waterproof engineering, and are widely used in various types of waterproof treatment.

Scope

1. Building roof waterproof:

For residential, factories, etc., prevent rainwater from penetrating and keep the building dry.

2. Tunnel waterproof project:

Using its high strength, wear resistance, and corrosion resistance to ensure the stability and safety of the tunnel structure.

3. Pool pool waterproof:

With water resistance and abrasion resistance, the long -term use of the swimming pool is ensured.

4. Equipment protection:

For industries such as chemical industry, electricity, pharmaceuticals, prevent equipment from being chemically corroded and worn, and extend the service life.

5. Multi -field applications:

Bridge decks, culverts, industrial flooring, and maritime drilling platforms are available. It has anticorrosive water and prevention, anti -seepage effects, and extend the service life.

Performance advantage

1. Waterproof overall.

The overall spraying process of the dedicated equipment is adopted, the waterproof structure is complete, and the waterproof layer is continuously seamless, which avoids hidden dangers of leakage caused by coil joints.

2. Convenient construction:

The spraying or pouring process is high -efficiency, no need to cut stitching, and is suitable for various curved surfaces and vertical surfaces.

3. Strong environmental adaptability:

Not affected by temperature and humidity, it can be constructed in harsh environments and has excellent physical and chemical performance.

4. High flexibility and flexibility:

The material has excellent elasticity and flexibility, can adapt to the deformation of the substrate, and effectively prevent leakage caused by the deformation of the base material.

5. CICC, fast and strong adhesion:

10 seconds to be solidified, bonding firmly with a variety of substrates, and forming no seam coating.

6. Environmental safety:

Double -components and zero VOCs, no pollution construction, are friendly to the environment, and can maintain high waterproof performance in the air.

7. Aging and long life:

The service life is long, which can reach 30 years, which greatly reduces maintenance costs.

8. Chemical corrosion performance:

It can resist the erosion of chemicals such as rainwater, pH, saline and alkali, and maintain the structure of the building stable and durability.

9. Excellent comprehensive performance:

It overcomes the defects of traditional waterproof materials and provides a reliable, efficient and environmentally friendly solution for waterproof projects.

Technical parameter

| Summary of the test results | |||||||

| serial number | Testing Project | Unit | Detection Results | Indicators ① | Detection Conclusion | Detection Method | Remarks |

| 1 | Solid content | % | 99.6 | ≥98 | Follow | GB/T23446-2009 | 120 ℃, 3H |

| 2 | Gel Time | s | 10 | ≤45 | Follow | GB/T23446-2009 | - |

| 3 | Time to watch | s | 12 | ≤120 | Follow | GB/T23446-2009 | Method: Refers to touch method |

| 4 | Stretch strength | MPA | 17.2 | ≥16.0 | Follow | GB/T23446-2009 | No processing |

| 5 | Fracture and elongation | % | 578 | ≥450 | Follow | GB/T23446-2009 | |

| 6 | Tear intensity | n/mm | 56 | ≥50 | Follow | GB/T23446-2009 | - |

| 7 | Low temperature bending | - | -40 ° C, no crack | ≤ -40 ℃ | Follow | GB/T23446-2009 | - |

| 8 | Different water | - | 0.4MPa, 2H, impermeable water | 0.4MPa, 2H, impermeable water | Follow | GB/T23446-2009 | - |

| 9 | Heating and Extending Rate | - | Eliminate 0.3% | Eligibility ≤ 1.0% | Follow | GB/T23446-2009 | - |

| 10 | Water absorption rate | % | 2.9 | ≤5.0 | Follow | GB/T23446-2009 | Soak in water for 7 days in water |

| 11 | Dispostering time | - | crackless and deformation | crackless and deformation | Follow | GB/T23446-2009 | Heating aging (80 ° C, 168h) |

| - | crackless and deformation | crackless and deformation | Follow | GB/T23446-2009 | Audging artificial climate (cycle A, irradiation strength 0.51W/m2, blackboard temperature 63 ° C, temperature in the box 38 ° C, 250h) | ||

| 12 | Hiking Treatment (80 ° C, 168H) | ||||||

| Stretch strength maintenance rate | % | 94 | 80-150 | Follow | GB/T23446-2009 | - | |

| Fracture and elongation | % | 619 | ≥400 | Follow | GB/T23446-2009 | - | |

| Low temperature bending | - | -35 ° C, no crack | ≤ -35 ℃ | Follow | GB/T23446-2009 | - | |

| 13 | Alkali treatment (0.1%NAOH+saturated CA (OH) 2,168h) | ||||||

| Stretch strength maintenance rate | % | 81 | 80-150 | Follow | GB/T23446-2009 | - | |

| Fracture and elongation | % | 593 | ≥400 | Follow | GB/T23446-2009 | - | |

| Low temperature bending | - | -35 ° C, no crack | ≤ -35 ℃ | Follow | GB/T23446-2009 | - | |

| 14 | acid treatment (2%H2SO4, 168H) | ||||||

| Stretch strength maintenance rate | % | 81 | 80-150 | Follow | GB/T23446-2009 | - | |

| Fracture and elongation | % | 629 | ≥400 | Follow | GB/T23446-2009 | - | |

| Low temperature bending | - | -35 ° C, no crack | ≤ -35 ℃ | Follow | GB/T23446-2009 | - |

PRODUCTION BASE

The company is committed to product technological innovation and building new platforms to improve its capabilities. In order to continuously improve its core competitiveness in the market and meet new market demands, Des-Lead has established a research and development center. The company has more than 10 professional R&D teams in the fields of flooring, sports, waterproofing and anti-corrosion, and polyurea. It continues to research products that better meet market needs, pays attention to ecological construction, and actively tries environmental protection technology. It has maintained vigorous vitality and abundant market vitality in the fierce market changes and market competition.

PRODUCTION LINE

Des-Lead has its own independent production base and has established a world-leading fully automatic assembly line with a comprehensive daily output of 100 tons and an annual service site area of more than 10 million square meters. The strict quality management system ensures the quality and efficiency of Des-Lead products.

RELATED PRODUCTS

ONLINE MESSAGE