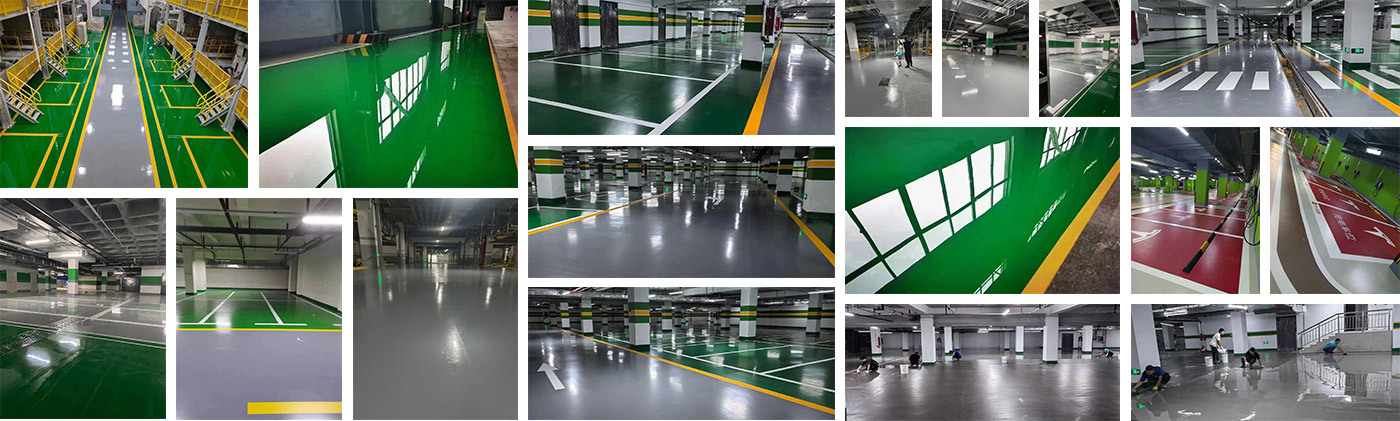

Underground garage floor

Classification:

Application Scenario

Key words:

Application Scenario

The underground garage floor coating system is composed of three parts of parking space, garage aisle, and anti -slip ramp road. The parking spaces and garage in the underground garage and garage in the lane can be referred to the solvent -free epoxy in the same way as the construction technical requirements and construction regulations. Ping and solvents epoxy flat -coated floor, but the slippery ramp requires special design and construction in accordance with special regulations. No shocking and stopping tract is a mineral orthopedic orthopedic with extremely high polygonal hardness. Special cement, other blending agents and external agents are composed of special crafts on -site construction. The commonly used colors are yellow bottom layers, green surface layers, yellow bottoms, 12 cm, the green surface is about 60 cm width, and the blunt angle is about 150 °.

No vibration stop lane design:

The lane non -skid material is processed by a reasonable ratio of modified resin, brown jade, and quartz sand.

The specially treated lane non -slip material has the advantages of good strength, high hardness, wear resistance, and weight -resistant.

After construction, a 3-6mm rule ramp is formed, with uniform specifications, large undulating small surface resistance, and vehicle driving on it has a good comfort.

The superior anti -corrosion, resistance, and beautiful surface effect can particularly meet the needs of modern properties. It is currently an ideal non -slip ramp.

Scope of application:

Large parking lots go up and downhill, with special requirements on the road to stop slippery, and the ramp of large loading areas.

Performance characteristics

1. Seamless surface, beautiful and generous

2. There is no vibration when the vehicle enters and exits

3. Abrasion, pressure resistance, impact resistance, ultraviolet -resistant skid lane

Construction process:

1. Base treatment: The original concrete surface must be fully cleaned up, the surface should be dry, no drums, no debris.

2. Primer: Use roller coating to build a closed bottom coating.

3. Under the layer: Mix the yellow background with the dedicated glue and the ground is full.

4. Facial designs: Paste it according to the design pattern with the tape.

5 surface layer: After the bottom layer is dry, mix the green fabric with the special glue and use a special spray gun to construct the surface layer.

Surface maintenance:

After the surface of the colored anti -slip layer reaches saturated and dry, the entire surface of the surface is sprayed with acrylic polymers for a week of ingenuity. Try to avoid passing within 3 days after construction.

PRODUCTION BASE

The company is committed to product technological innovation and building new platforms to improve its capabilities. In order to continuously improve its core competitiveness in the market and meet new market demands, Des-Lead has established a research and development center. The company has more than 10 professional R&D teams in the fields of flooring, sports, waterproofing and anti-corrosion, and polyurea. It continues to research products that better meet market needs, pays attention to ecological construction, and actively tries environmental protection technology. It has maintained vigorous vitality and abundant market vitality in the fierce market changes and market competition.

PRODUCTION LINE

Des-Lead has its own independent production base and has established a world-leading fully automatic assembly line with a comprehensive daily output of 100 tons and an annual service site area of more than 10 million square meters. The strict quality management system ensures the quality and efficiency of Des-Lead products.

RELATED PRODUCTS

ONLINE MESSAGE